manufacturing partner

your electronic

manufacturing partner

At LM Electronic we have 30 years of experience in EMS. On three assembly lines we mount all types of rigid PCBs for our customers. Those are mainly industrial users as well as international lighting companies in the high end segment. Batch size varies from samples to large scale production. The Selective Soldering of THT components is fully automatized.

Precision & Process Stability

With screen printers by GKG and EKRA we are well equipped for all tasks. For a maximum of process stability and highest quality we always monitor the screen print results using solder paste inspection (SPI)

Using our GKG PMAX II we can print longboards up to a maximum size of 1220mm x 800mm.

High performance in XXL

With a maximum PCB size of 1220mm x 560mm we are able to mount boards in unusually large sizes.

We offer up to 160 slots for 8mm single feeders and one MTC per line which allows us to serve a wide spectrum of different components.

Our SMD mounters of type JUKI 3020 and RX6 are equipped with multi nozzle vision centering for optimal process stability mounting BGAs and QFPs.

Individual and gentle

For your individual board we create a tailor made and optimized soldering profile.

Besides standard reflow ovens we also offer the possibility of vapour phase soldering (VPS) using Asscon batch oven.

maximum inspection performance

Our AOI by German manufacturer Schneider & Koch is a reliable machine for daily use.

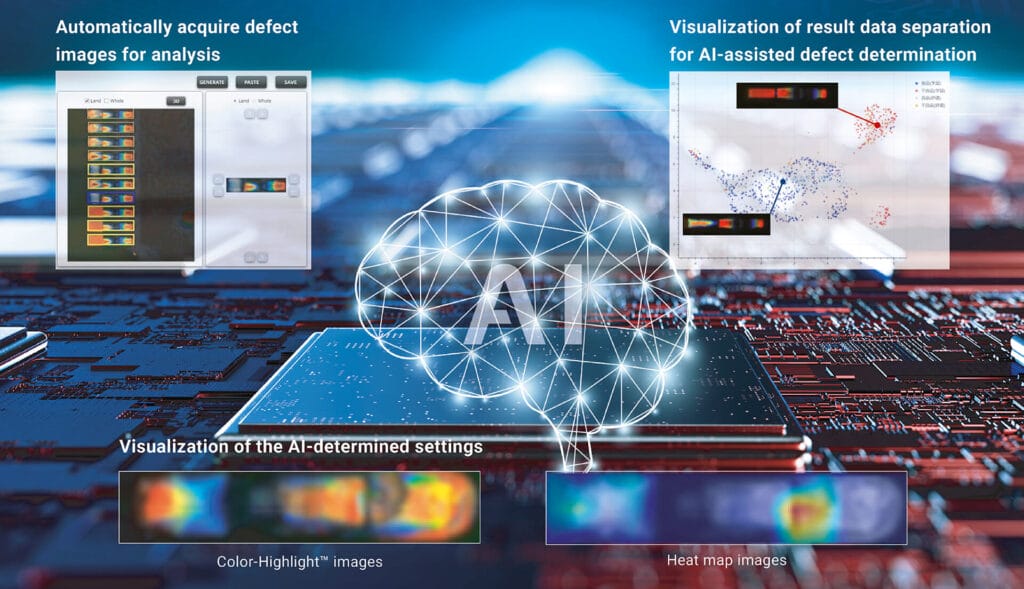

In September 2025 we are going to install our new High Performance 3D AOI – Omron 1080. With AI supported programming and 4 side cameras it uses latest software and intelligence to offer the maximum of optical inspection for your electronics.

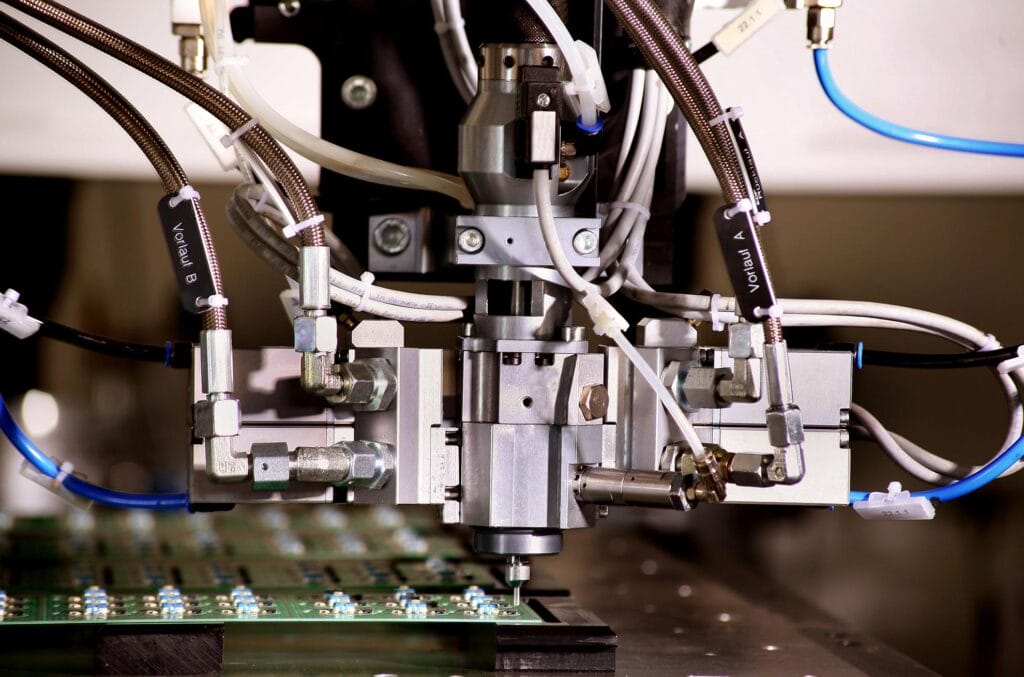

Through Hole Technology

THT components we solder automatized and in-line.

We combine high output with monitored quality.

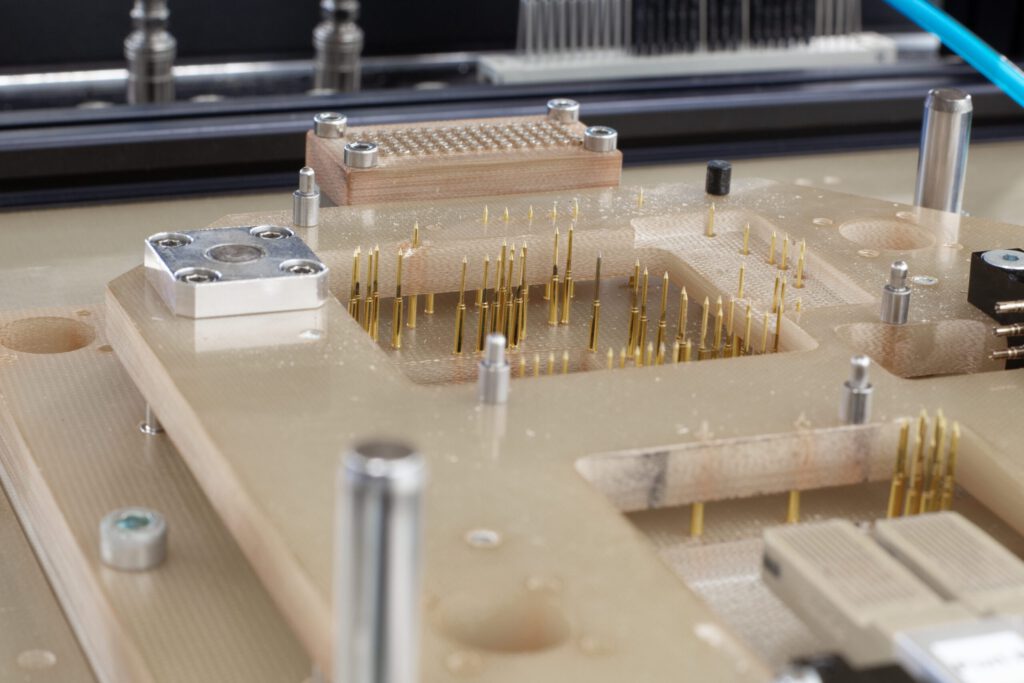

In Circuit Testing

Since August 2025 we additionally offer In Circuit Testing (ICT) for our customers.

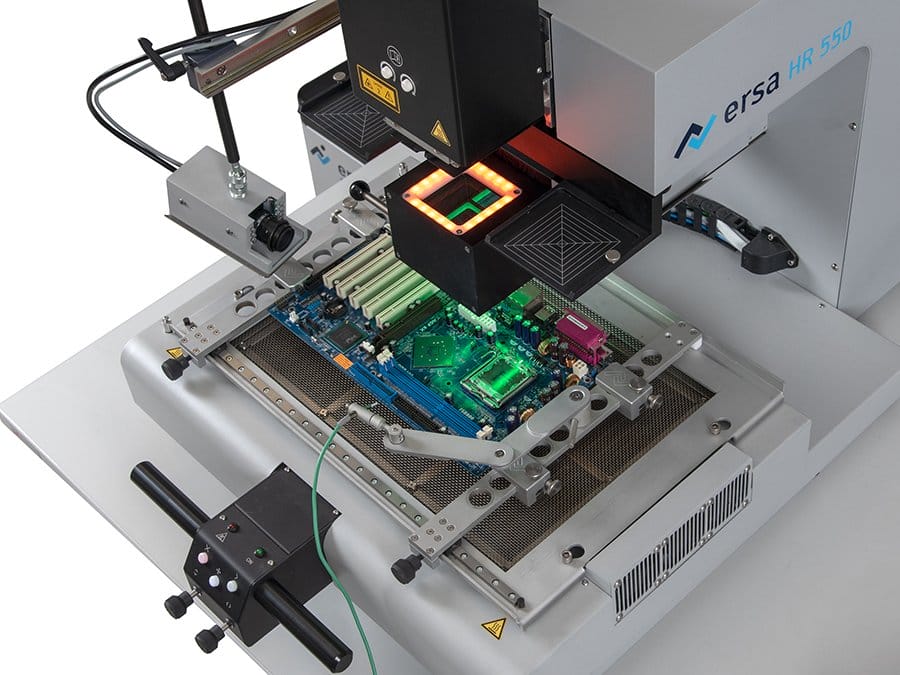

BGA repair with camera based precision

Our service includes complex repairs and rework of components like expensive ICs or BGAs.

It is performed with a market leading rework station.

LM Electronic provides the procurement of components, SMD assembly as well as testing of PCBs. You receive electronics in highest quality from a single source, including complete device assembling and shipping to your end customer.

Our customers benefit from 30 years of experience: As a Full Service Provider (FSP) we support you in each step from development and engineering as well as manufacturing electronic boards of all types, including inspection and testing. We are happy to go the extra mile as Your Electronic Manufacturing Partner (EMP)

characteristics

Over 30 years of experience

3 SMD lines

XXL Long Boards

Inline Vapor Phase

Full Service Provider

Automated rework

per year